The international scientific conference WPC25 Vitrintec took place on September 25–26, 2025, at the Nosalowy Dwór Resort & Spa in Zakopane. The event was organized by the Faculty of Non-Ferrous Metals of AGH University of Science and Technology and the AGH UST Laboratory of Extrusion Processes. QForm Group was a Sponsor of this event. This year’s conference focused on aluminium alloy extrusion technologies. Key topics included:

Ecology and sustainability – aluminium recycling and smelting of ingots from post-production and post-consumer scrap, leading to low-carbon-footprint extruded profiles

Process efficiency – optimization of the extrusion process through various die cooling systems, including additive methods and 3D printing

Advanced applications – highly processed extruded components for sustainable and energy-efficient construction

.jpg)

.jpg)

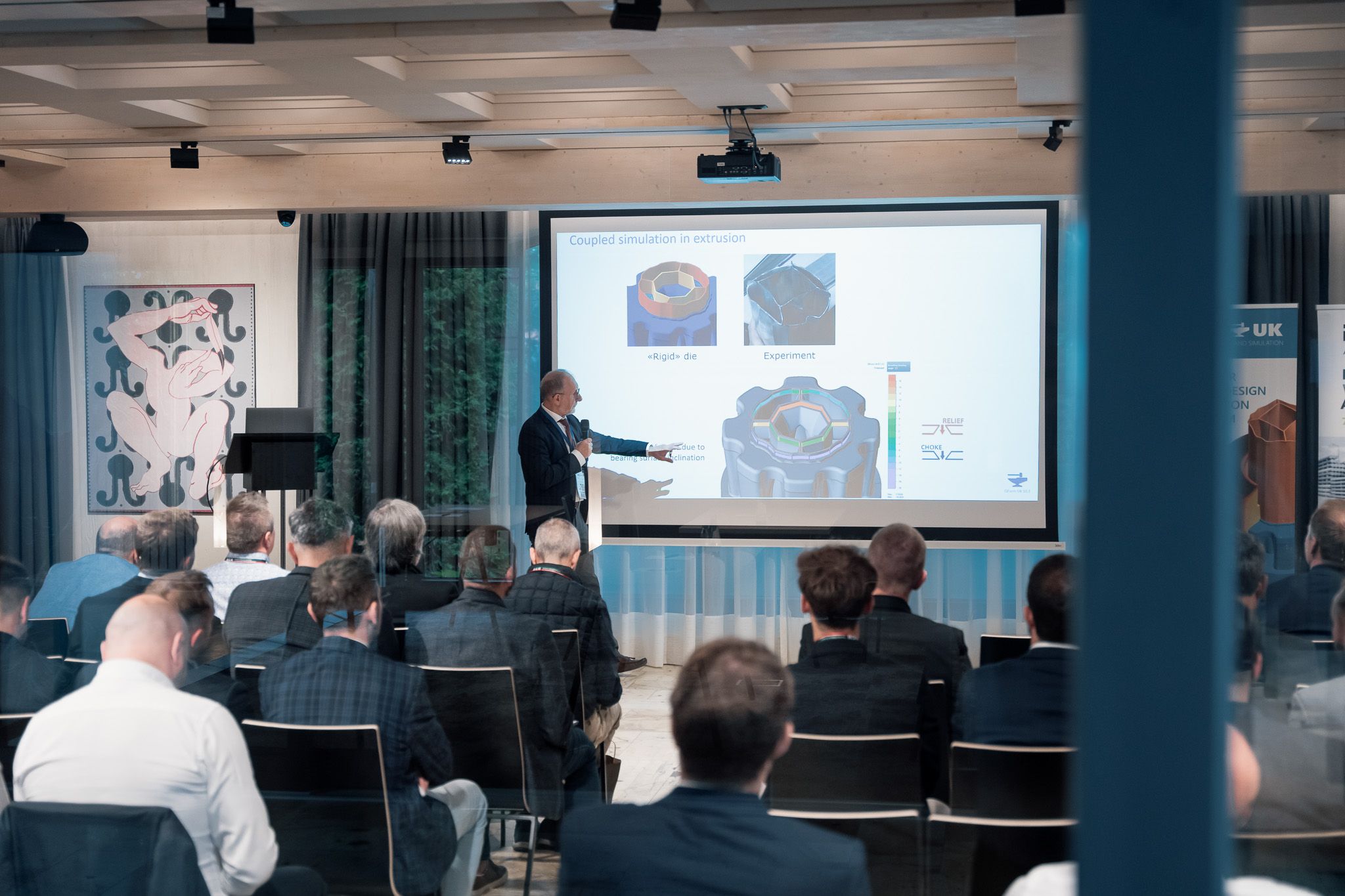

At the conference, Nikolay Biba presented a new solution: Extrusion Link – a new Industry 4.0 platform for collaboration and data exchange between extruders and diemakers. This concept significantly simplifies interaction between tool manufacturers - extruders - and finally consumers of aliminium profiles.

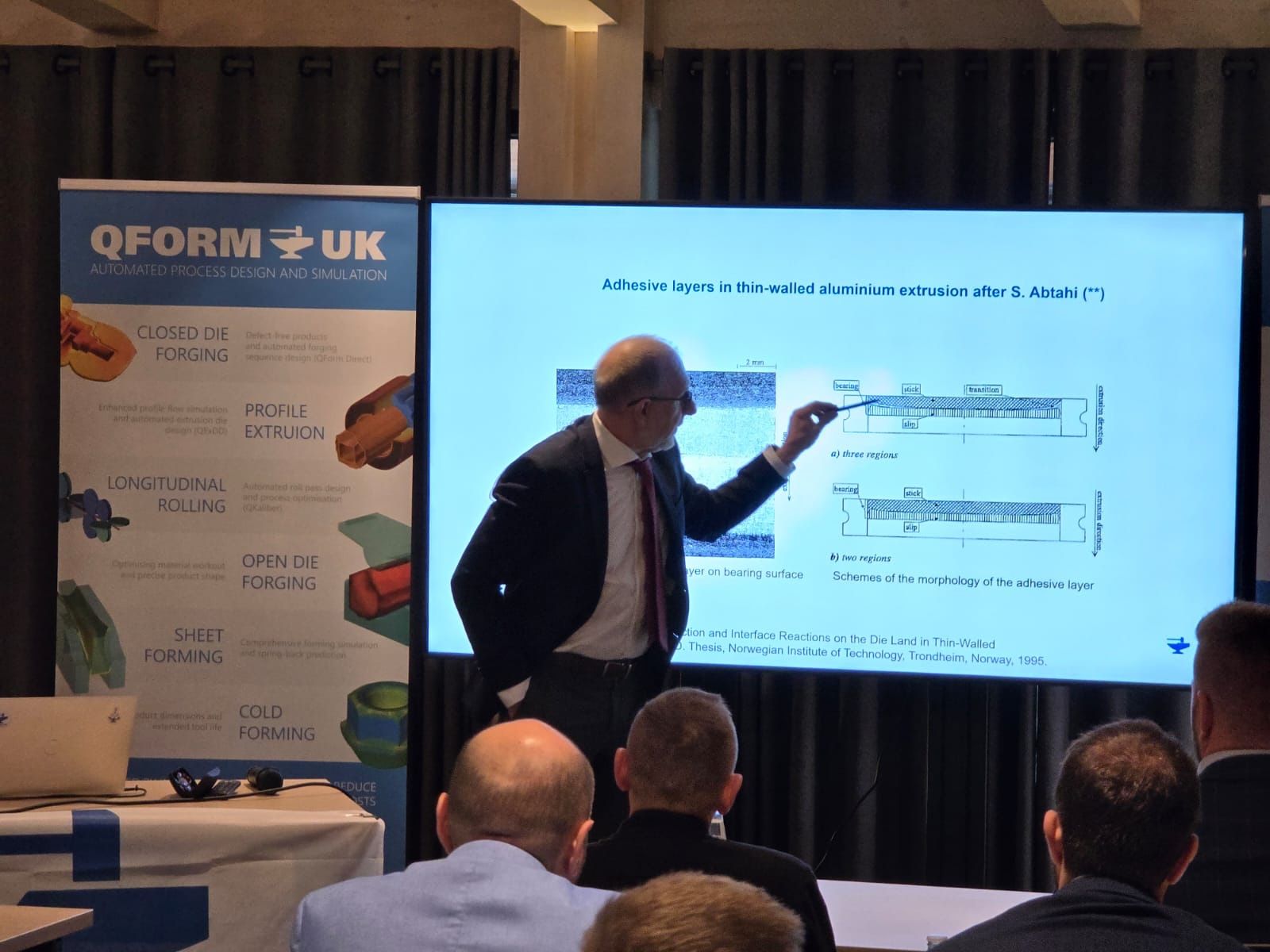

Following the conference, participants attended the Basic Course on Aluminium Extrusion, organized by QForm Group in collaboration with the AGH UST Extrusion Process Laboratory.

The course featured lectures from leading experts, including Dr. Eng. Jacek Madura (AGH University of Science and Technology, Faculty of Non-Ferrous Metals), Nikolay Biba (Micas Simulations Ltd., QForm Group), Paul Mordvintsev, and Rudolf Kenig.

.jpeg)

.jpg)

The training covered:

Mastering modern capabilities for extrusion process design and optimization

Gaining knowledge on tool optimization through simulation analysis

Acquiring basic skills in modern design and simulation software

Learning the principles of preparing input data for extrusion process simulation

Developing expertise in analyzing and interpreting simulation results