General Metal Forming Simulation is the core software for simulating and optimizing metal forming processes. It forms the basis of the QForm system and supports the simulation of a wide range of forming operations.

To extend its capabilities, various specialized modules can be added, such as extrusion, rolling, microstructure, and heat treatment simulation, among others.

Using subroutines and APIs, QForm helps avoid routine tasks and saves valuable time for specialists, freeing them up for creative problem solving. Simulation results can be presented in an easy-to-understand format using automatically generated templates customized to your company's standards.

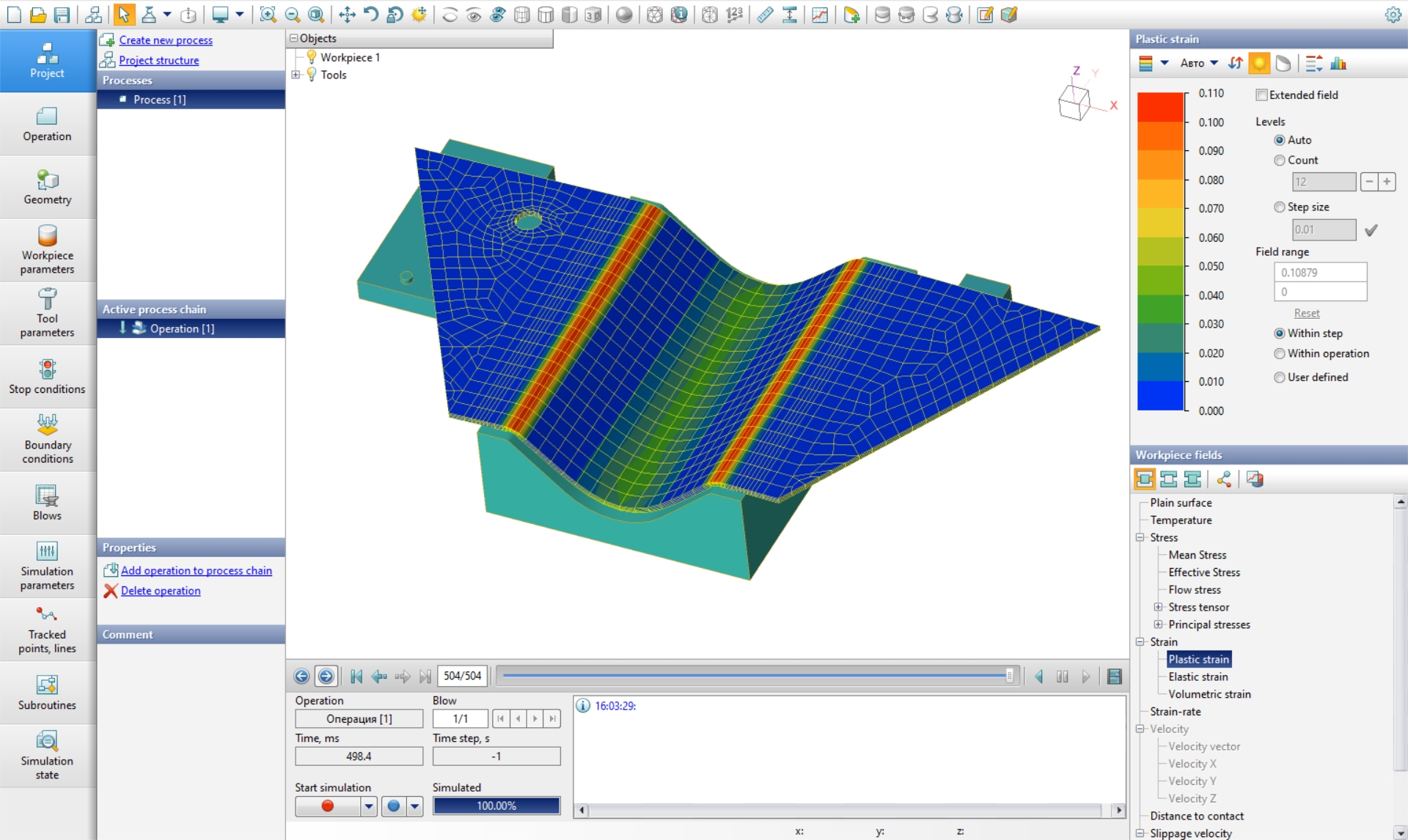

The new algorithms enable highly efficient use of modern multicore processors and system resources, delivering substantially faster simulations. Because the solver and user interface operate separately yet concurrently, results can be displayed in real time, even during complex simulation runs.

Users can set initial parameters, control the simulation process, and analyze results within a single, integrated interface. A wide range of tools helps users easily define complex technological processes and conveniently explore the extensive data generated by the simulation.

The creation of the finite element mesh and the rebuilding of the mesh during simulation are performed automatically and, as a rule, do not require user involvement.

QForm software allows simulation of forgings using powdered metal workpieces. Relative density field during the forging process is shown.

Before implementation of the QForm software the initial forging technology had a flow-through defect. The exact location of the defect was identified by the simulation. The under-surface flow lines in QForm show this defect which is marked out on the photo presented in this video.

By means of the simulation it was easy to understand the reason of defect formation. Then the central part of the die impression was modified to escape the defect. The comparative analysis of the initial and optimized tool geometry is shown in the video.

The second part of the video shows the simulation results for the optimized technology where the defect is not appeared.