Open Die Forging Simulation Module

Modern finite element simulation software that enables fast, accurate, and economic development of open die forging processes, eliminating the need for trial-and-error methods

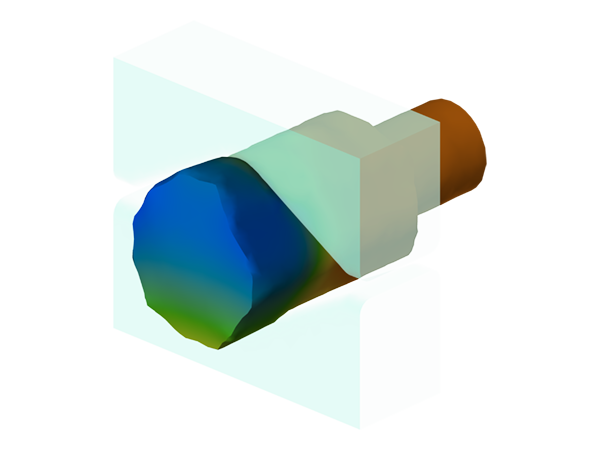

Real-life simulation for large-scale forgings

Material flow prediction depending on tool shape, rotation and/or axial movement between blows

Calculating thermo-elastic-plastic stresses during heating and cooling to predict the possibility of cracks

Possibility to predict macro and microstructure on the computer during development of the process

Simulation of complicated regimes of heating and cooling, necessity of inter-operation heating

Possibility to predict changing of axial billet porosity during forging of cast billet

Optimizing hammer forging with QForm simulation

This video demonstrates the optimization of stub axle hammer forging using QForm. Initially, laps formed during the process, but by increasing upsetting and flattening heights, defects were eliminated. The optimized forging shows a defect-free final part.

Dual mesh method for fast and accurate simulation of processes with many blows and localized deformation zone

Convenient table interface to set multi-blow operations: automation of rotation and/or axial movement between blows

Special model of forging manipulator for easy simulation of manipulator

Simulation of heat treatment and thermomechanical processing of billet

Get QForm Demo

Fill out this form and we will contact and and offer best conditions for your production scale and industry